Rapid Prototyping

With our rapid prototyping services, Elmi Machine & Tool Co. helps customers realize their design concepts. Our programmers and machinists work at a fast pace to produce machined prototypes with the physical properties that correspond precisely to the actual product. By supplying a hands-on version of a product that coincides with the desired dimensions and features, we give clients the opportunity to prove out their concepts, assess product usability, and make improvements. Prototypes enable our customers to share the design with stakeholders and carry out form, fit, and functional studies using a model that is as close as possible to the final product.

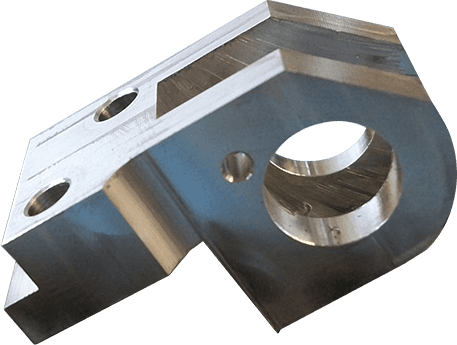

We leverage both conventional and CNC machining methods to produce rapid prototypes. Along with a selection of metals and polymers, we build prototypes from materials such as ceramics and elastomers. We manufacture products that measure as small as 0.1” in diameter and 0.008” in length or as large as 8.0’ long x 20.0” wide x 18.0” high. For projects where precision is of paramount importance, we can uphold tolerances as close as ±.00002”.

We have staff available to carry out design-for-manufacturability assessments to aid in product development, and we also provide fabrication and assembly services as needed. Whether requirements call for a visual prototype or a high-fidelity model for use in tooling development or short-run production, we offer a standard turnaround of one to two weeks, depending on the complexity. Our rapid prototype department is also set up to react quickly to rush and emergency situations to allow turnover of jobs as soon as one to two days. As a 3rd generation company with a 50-year history in the prototyping business, we are a reliable source for high-quality prototypes. To learn more about our rapid prototyping capabilities, contact us today.