CNC & Manual Milling

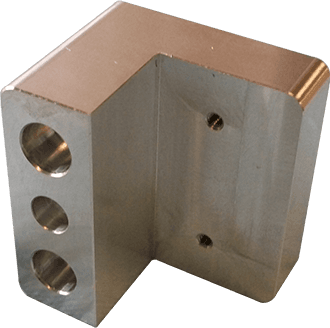

As part of our complete manufacturing solutions, at Elmi Machine & Tool Co. we offer both CNC and manual milling as a standard service. Capable of producing very detailed and accurate parts, we have an arsenal of horizontal milling machines as well as a vertical 4-axis mill. With equipment that features live tooling, powerful electric and pneumatic drive motors, variable spindle speeds, and power-operated table feeds, we have the capacity to handle large-scale production runs. We also offer competitive pricing and fast turnover for prototyping and short-run work.

We use CAD/CAM software packages to optimize cutting parameters for maximum milling and finishing cycle effectiveness. With our extensive library of high hardness cutting tools for profiling, drilling, tapping, countersinking, and boring, our highly skilled staff can choose the best options for optimal feeds, speeds, stock removal, detail work, and finishing. We have in-depth experience working with all types of metals, including difficult to machine alloys such as Hastelloy and others with high chrome or nickel content. Our capabilities also include machining plastics and other non-metals, including graphite, ceramic, fiberglass, and others.

We mill tiny parts with dimensions as small as 0.10” square or those measuring as large as 8.0’ in length x 20.0” in width x 18.0” in height. With our precision milling capabilities, we obtain tolerances as close as ±.0002”. As a lean manufacturing company, our processes are geared for efficiency as well as optimal quality and part-to-part consistency. We inspect all milled parts to ensure they meet the specified quality criteria.

As a 3rd generation company with a history that dates back more than 50 years, we understand the value of providing exceptional customer service. We work hard every day to ensure all deadlines are met and parts ship on time. To learn more about our CNC and manual milling services or to request a quote, contact us directly.